MILDTL19491J

4.5.1.2 Visual and dimensional inspection. Visual and dimensional inspection shall consist of those inspections

specified in table I.

4.5.1.3 Sample plan. A sample of five packages shall be randomly selected. If one or more defects are found, the

inspection lot shall be screened and the defective packages removed. A new sample of five packages shall be

randomly selected. If any of the defects are found in the second sample, the inspection lot shall be rejected and shall

not be supplied as in compliance with this specification.

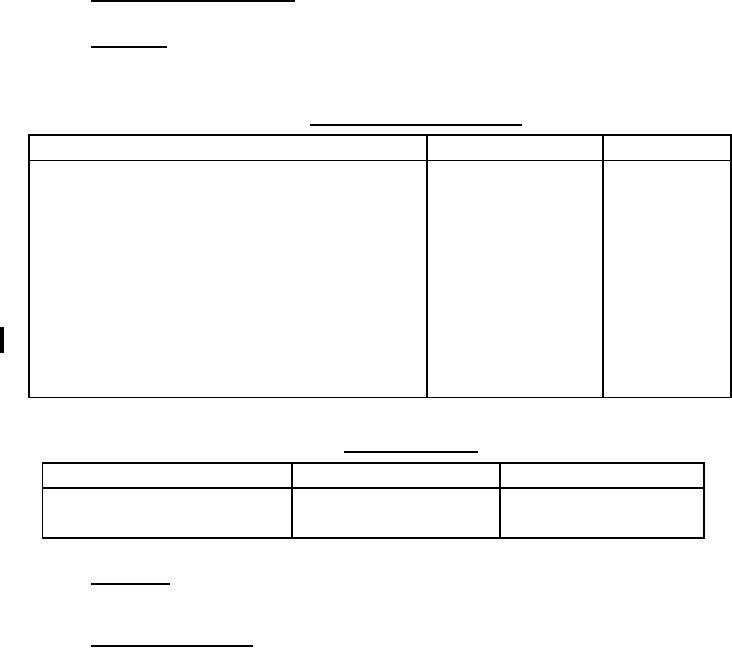

TABLE I. Visual and dimensional inspections.

Major defects

Requirement paragraphs

Method paragraph

Packaging materials not conforming to referenced specification

requirements

Insufficient field force protection (shielding)

Punctured or improperly fabricated barrier bag

Unclean or improperly cleaned items

Incorrect preservation method

Wrong quantity per unit pack

Non-usable or incorrect applications of intermediate containers

Improper box closures

Omitted, incorrect, or illegible marking

TABLE II. Functional inspections.

Major defects

Requirement paragraph

Method paragraph

Rough handling (when specified)

Leakage (when applicable)

4.5.1.4 Rejected lots. If an inspection lot is rejected, the contractor may rework it to correct the defects, or screen

out the defective units, and resubmit for reinspection. Resubmitted lots shall be inspected using tightened inspection.

Such lots shall be separate from new lots, and shall be clearly identified as reinspected lots.

4.5.1.5 Disposition of sample units. Sample units, which have passed all the inspections specified in table I may

be delivered on the contract, provided the lot is accepted.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business