MIL-DTL-2845E (SH)

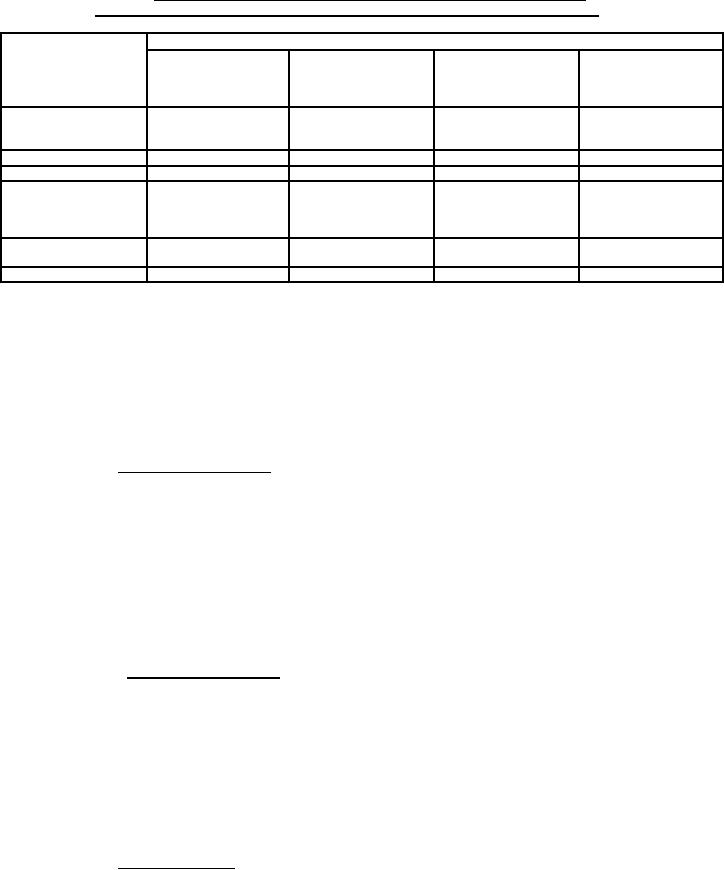

TABLE IV. Sizes of members in skid assemblies for shipment

of propulsion shafting greater than 3 inches in diameter.

of:

Size of members for shafts with diameters

16 to 24

8 inches to

Greater than 3

Greater than 24

Item

inches

Inches

less than 16

inches but less

(inches)

inches

than 8 inches

(inches)

(inches)

(inches)

4 by 6 (flat) or 4 by 8 (flat)

6 by 8

4 by 4 or two

Skids

2 by 3's (flat)

two 2 by 6's

(flat)

End headers

4 by 4

4 by 6 (flat)

4 by 8 (flat)

4 by 8 (flat)

Cross skids3/

3 by 4 (flat)

4 by 4

4 by 4

4 by 4

Two 4 by 12's to

Two 4 by 16's

Cradles1/

Two 4 by 6's

Two 4 by 8's to

4 by 16 laminate

and larger

(cutout)

to 4 by 8

4 by 12

with 3/4-inch

laminate with

plywood

3/4-inch plywood

Cradle2/ spacing

20

36

2-1/2 times

2 times diameter

(maximum)

diameter

Lagging

1 by 2

2 by 2

2 by 2

2 by 2

1/

Cradles shall be fabricated in two equal parts, the bottom and top

halves cut to fit the shaft snugly with allowance for preservation, wrapping,

lagging, or other protection. Laminated cradles shall be used for shafts

exceeding 16 inches in diameter.

2/

The number and location of cradles shall be adjusted so that they are

located at the quarter points for sling lifting. The maximum spacing between

cradles is limited to 4 feet.

3/

Cross skids shall be located at each cradle and shall be bolted to

the skids with the same bolts used to fasten the cradle.

3.15.7 Shaft accessories. Shaft accessories such as keys and propeller

nuts shall be cleaned and preserved as specified for shafting in 3.15.2. Shaft

accessories shall be individually wrapped with a barrier material in

accordance with MIL-B-121, type 1, grade A, class 2. Accessories shall be

packed in a single wood or metal box braced to prevent movement during

transportation. Wood materials utilized for container construction shall be as

specified in 3.8.2.2 for multiple trip use. The accessory box shall be

permanently attached to the shaft skid base. The use of dunnage as a filler

material is prohibited. The box shall be assembled with corrosion resistant

(stainless steel) screws. The top cover of the box shall be attached with hex

head corrosion resistant (stainless steel) screws to permit ready removal and

installation of accessories.

3.15.8 Technical reports. When the item specification requires the

technical report be included with the shipment, technical reports shall be

enclosed in a minimum 0.004-inch thick transparent, waterproof, greaseproof

resealable bag (zip-lock or equivalent) to permit removal and replacement of

the technical report. The bag shall be prominently marked "Technical Report".

The technical report shall be placed in a wood box of suitable size for the

report. The wood box shall be permanently affixed to the shaft skid type

base. Wood materials utilized for the technical report box shall be as

specified in 3.8.2.2 for multiple trip use. The top of the technical report

box shall be attached with corrosion resistant hex-head screws to permit

removal and replacement of the report.

3.15.9 Shaft marking. Shaft markings shall be stenciled on the outer

layer of packing or container. Marking shall be 1 inch in height. Markings

shall be applied in accordance with MIL-STD-129 / MIL-HDBK-129 except that

wood containers shall be stenciled in all capital letters. A contrasting

color oil based paint shall be applied to the wood surface prior to

26

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business