MIL-DTL-55330D

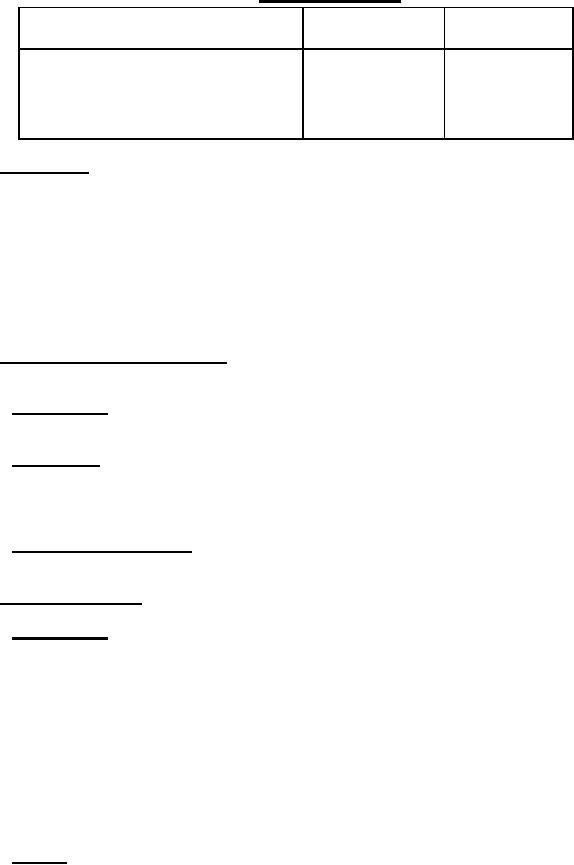

TABLE II. Functional inspection.

Test

Requirement

Method

paragraph

paragraph

3.5.1.1

4.6.2.1

Rough handling (when specified)

3.5.1.2

4.6.2.2

Leakage (when applicable)

4.4.1 Inspection lot. An inspection lot shall consist of unit or exterior (shipping) packs produced under

essentially the same conditions and offered for inspection at one time. For the purpose of selecting

samples to be inspected and tested for compliance with the requirements of this specification, either

items in process or completed packs, except as stated herein, may be combined into lots without regard

to individual items, contracts, or the quantities therein. Unit packs of the same size and made from the

same packaging materials may be grouped together except when item complexity, item value, or the

complexity of the preservation method warrants that the inspection of such items be performed on a

separate basis. A separate application of the sampling or inspection procedure shall be made on these

Items. The combination of items to be subjected to inspection shall be determined by either the

government or the contractor, subject to the approval of the Government.

4.4.2 Visual and dimensional inspection. Visual and dimensional inspection shall consist of those

inspections specified in table I.

4.4.2.1 Sampling plan. Statistical sampling and inspection shall be in accordance with ASQC�Z1.4.

There shall be no failures for all inspections of table I combined.

4.4.2.2 Rejected lots. If an inspection lot is rejected, the contractor may rework it to correct the

defects, or screen out the defective units, and resubmit for reinspection. Resubmitted lots shall be

inspected using tightened inspection. Resubmitted lots shall be separate from new lots, and shall be

clearly identified as reinspected lots.

4.4.2.3 Disposition of sample units. Sample units which have passed all the inspections specified in

table I may be delivered on the contract, provided the lot is accepted.

4.4.3 Functional inspection. Functional inspection shall consist of the tests specified in table II.

4.4.3.1 Sampling plan. Sampling plans shall be as follows:

One sample unit for the rough handling test shall be selected whenever the design of the item or

package Is changed.

For unit packs requiring waterproof or water-vaporproof barriers, five sample units for the leakage

test shall be selected daily at random from the first lot processed each day. Five additional

samples shall be selected at random from the day's total production.

The leakage test shall also be performed following the rough handling test on unit packs requiring

waterproof or water-vapor proof barriers. Five sample units or the number of units contained

within the shipping container (if less than five) shall be selected.

4.4.3.2 Failures. One or more failures shall be cause for rejection of the lot.

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business