MIL-DTL-55330D

4.2.2 Inspection conditions. Unless otherwise specified, all inspections shall be performed in

accordance with the test conditions specified in the general requirements of MIL-STD-202.

4.3 First article inspection. When specified (see 6.2), first article inspection shall be performed by the

contractor, after award of contract and prior to production at a time and location acceptable to the

Government.

First article inspection shall not be required if one or more of the following conditions are met:

a. When there have been no changes in materials, processes, or packaging design that will

adversely affect item protection since the last recorded inspection.

b. When the detailed packaging instructions are furnished by the acquisition activity.

c. When minimal protection is specified.

d. When a prior successful inspection was conducted on a like item and pack (subject to the

approval of the administrative contracting officer).

4.3.1 Sample size. One sample unit consisting of a military preservation, as applicable, fully packed

shipping container shall be submitted for first article inspection. The sample for the rough handling test

shall consist of the pack selected for first article inspection. The sample for the leakage test shall be five

unit packs selected at random from the first article exterior pack (shipping container).

4.3.2 Inspection routine. The sample shall be subjected to the inspections specified in tables I and II.

The leakage test, when applicable, shall follow the rough handling test.

4.3.3 Failures. One or more failures shall be cause for refusal to grant first article approval.

4.3.4 Resubmission of first article sample. If the sample fails to pass first article inspection, the

contractor shall change the preservation and packing processes to correct the cause of the deficiency.

First article inspection shall be performed on a corrected sample to prove that the corrective action is

acceptable.

4.4 Conformance inspection. This inspection shall consist of the inspections and tests specified in

tables I and II, respectively.

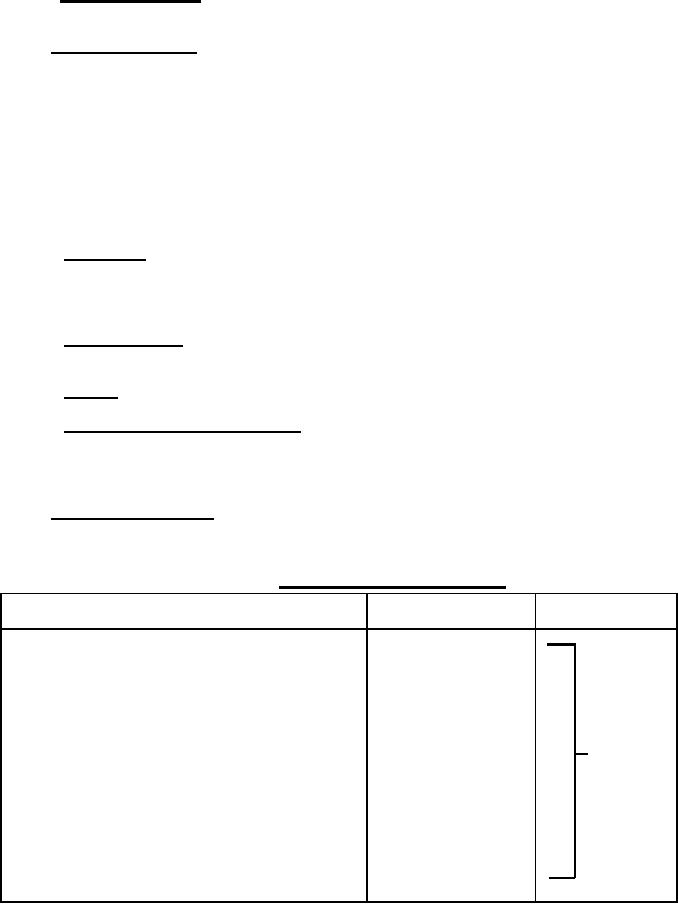

TABLE I. Visual and dimensional inspection.

Requirement

Method

Inspection

paragraph

paragraph

Uncleaned or improperly cleaned items

3.2.1.1 and 3.2.1.2

Punctured or improperly fabricated barrier bag

3.2.1.4.1 and 3.2.1.4.2

Incorrect preservation method

3.2.1.4.1 and 3.2.1.4.2

4.6.1

Wrong quantity per unit pack

3.2.1.4.1 and 3.2.1.4.2

Non-use or incorrect application of intermediate

3.2.1.5

containers

3.3.1 and 3.3.2

Improper box closures

3.4

Omitted, incorrect or illegible marking

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business