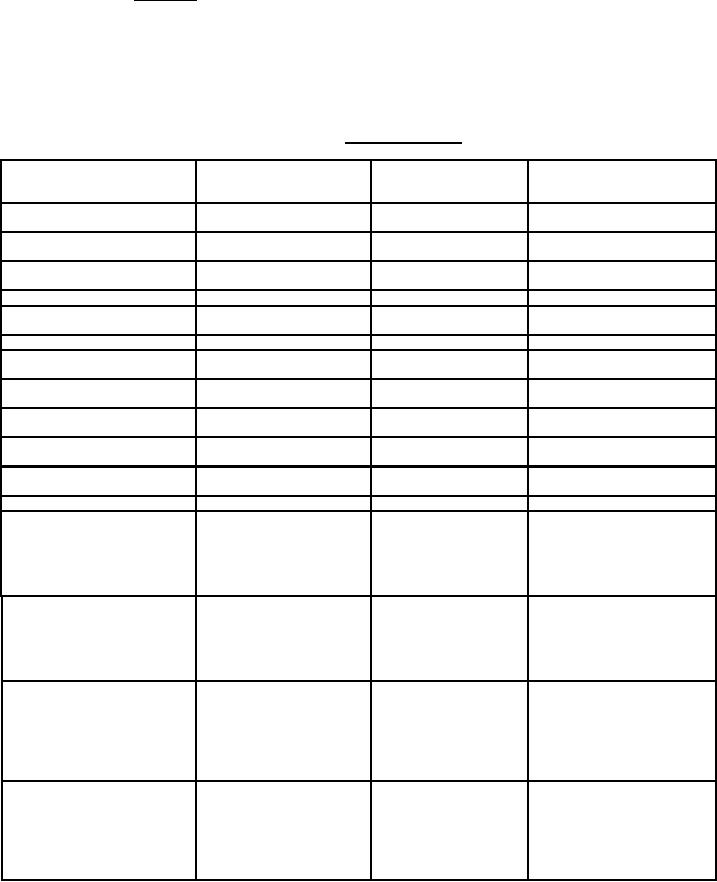

MIL-DTL-2845E (SH)

3.5.1.1 Level A. Cleaning, drying, preservatives, preservative

application criteria, and methods of preservation (unit protection) shall be

in accordance with MIL-STD-2073-1C (military preservation), and as specified

herein. Requirements in table I are assigned by item; methods of unit

protection are assigned on the basis of the type of unit protection most

commonly required for a specific component or item. The preservation activity

may provide any additional protection that is considered necessary with the

prior approval of the contracting activity.

TABLE I.

Preservation.

Method of

Preservatives

Item

preservation

Remarks

(MIL-STD-2073-1C)

Accessories

See 3.7.2.7 and

3.14.3

Sleeves shrunk on

See 3.15.2

shaft

Certification form for

See 3.14.5

propeller

Devices

See 3.14.8

Electrical and

See 3.7.2.5 and MIL-

electronic items

E-17555

Finished machined:

Steel shaft

See 3.15.2

surfaces

Bronze

See 3.15.2

shafts

Nickel-copper alloy

See 3.15.2

shafts

Full molded rubber or

None

Method 10

laminated phenolic

Line shaft and main

MIL-PRF-16173, GR 3

Method 20

See 3.7.2 and 3.7.3

thrust bearings

Technical manuals

None

Method 10

See 3.10

Miscellaneous finished

None

Method 10

bronze, brass, and

nickel-copper alloy

castings (stern tube

stuffing box and

gland)

Miscellaneous finished

None

Method 10

See 3.7.2.3

forged and rolled

brass, bronze and

nickel-copper alloy

parts (studs, rings,

and keys)

Miscellaneous finished

MIL-PRF-16173,

GR 1

Method 20

forged and rolled

MIL-PRF-16173,

GR 4

steel parts (coupling

or

or

bolts, nuts, washers,

MIL-P-3420

keys, and coupling

Method 30

MIL-B-22019

flanges)

MIL-B-22020

MIL-I-22110

Miscellaneous finished

MIL-PRF-16173,

GR 1

Method 20

steel and iron

MIL-PRF-16173,

GR 4

castings bulkhead

or

or

MIL-P-3420

stuffing box

MIL-B-22019

Method 30

MIL-B-22020

MIL-I-22110

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business