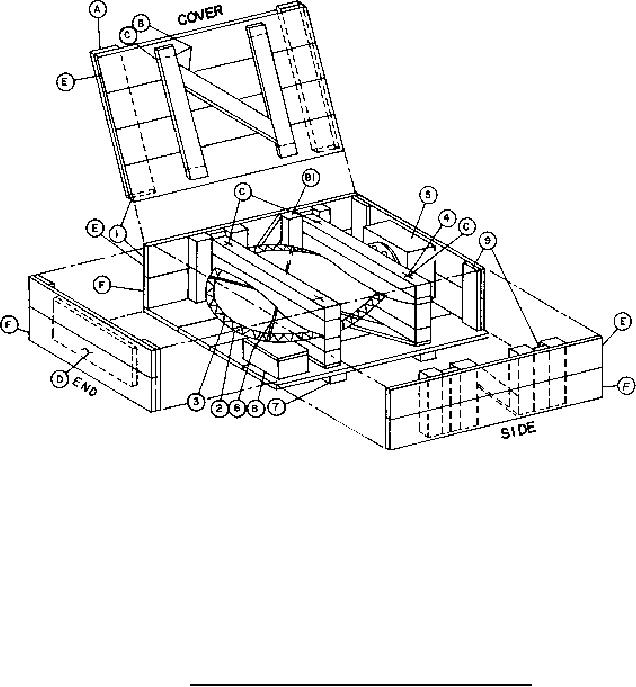

MIL-DTL-2845E (SH)

A.

Exterior cleats to prevent splitting of the ends of the cover members.

B.

Detail 4 is held in place by screwing through the sides and by pressure fit from the lid.

End grain screwing is not recommended, hence the use of pocket cleats B1 and the relocation

of the diagonal on the lid.

C. Another alternate to the pocket cleats B1 would be the use of tie down bolts running from

under the skid tot he top block holding the contoured saddle. To make clearance for the

bolts

the cross member under the top must be cut back.

D. To prevent severe end impact and give additional protection to the blade edge, a piece of

minimum 3/4" plywood should be fastened on the inside of the end panel.

1.

Box, type I, class I, style A, lengthwise sheathing 1-1/8" (30mm) wood planks.

2.

Edge guards according to 3.14.1.4.

3.

Canvas according to 3.14.1.4.

4.

Contoured saddle, cushioned, 4-23/32" * 4-23/32" (120 * 120mm) wood beams.

5.

Blocking device, wood piece.

6.

Edge guard fastening (steel strap).

7.

Skids 1-31/32" * 4-23/32" (50 * 120mm) wood beams.

8.

Wood case for accessories, bolted to bottom.

9.

Wood cleats, 1-3/16" * 4-23/32" (30 * 120mm).

FIGURE 3.

Propeller blade packing (see 3.14.2.1).

37

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business