MIL-DTL-197L

4.2.8 Magnetism. The measured magnetism of a bearing shall not exceed the specified

level for the preservation method used (see 3.3.3).

4.2.9 Requirements for method. Verify the requirements of section 3 have been

accomplished for the preservation method used.

4.3 Quality system. The contractor shall implement and maintain a quality system that

satisfies program objectives and meets the test, examination, and inspection requirements

contained in this specification.

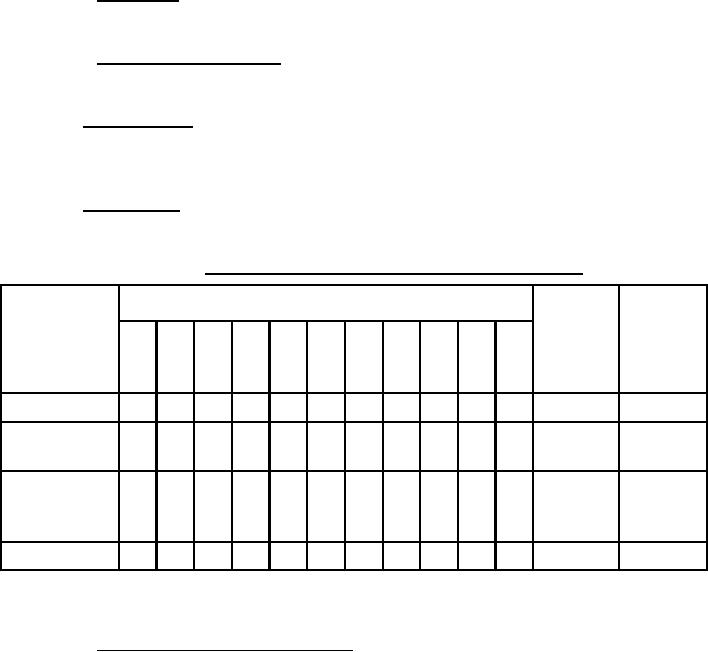

4.4 Test methods. Table IV shows the tests required for each applicable method. The

sampling requirements are also identified.

TABLE IV. Tests applicable to each method of unit preservation.

Method number

Sampling Reference

52B

Inspection/test

paragraph paragraph

20B 32B 33B 40B 41B 44B 45B 46B 49B & 54B

55B

X1 X1

X1 X

Leakage

-

-

X

X

-

-

-

Heat-sealed

-

X

X

-

X

-

-

-

-

X

X

seam

Fingerprint

corrosion &

cleanliness

Corrosion

-

-

-

X

-

-

-

-

-

-

-

1

Leakage test is not required for bulk quantities.

2

Plain self-lubricating bearings, sleeves, and rod ends shall not require the fingerprint corrosion test.

4.4.1 Leakage and heat-sealed seam tests. Sample specimens shall be selected in

accordance with 4.2.1.1.1. The leakage and heat-sealed seam test shall be in accordance with

methods 5009 and 2024 of MIL-STD-3010. Bag heat seals shall be checked or tested daily.

a. The leakage tests shall be performed in accordance with method 5009 of

MIL-STD-3010. The requirement for the technique used for this test shall depend on the method

of preservation used in the packaging process. It is possible that the contractor will use one or

more techniques in performing the leakage test.

b. The heat seal seam test shall be conducted in accordance with method 2024 of

MIL-STD-3010. In addition, the test shall be performed at room temperature using a static load

weight as specified herein. When the barrier materials conform to A-A-3174, MIL-PRF-121,

MIL-PRF-131, or MIL-PRF-22191, the static load weight shall be 56 ±0.5 ounces. Heat seals

shall not separate during the final 3 minutes of the test. Partial separation in the area of partial

fusion adjacent to the actual seam is acceptable within the first 2 minutes of the test. The weight

shall be allowed to act for a minimum of 5 minutes.

28

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business