MIL-DTL-197L

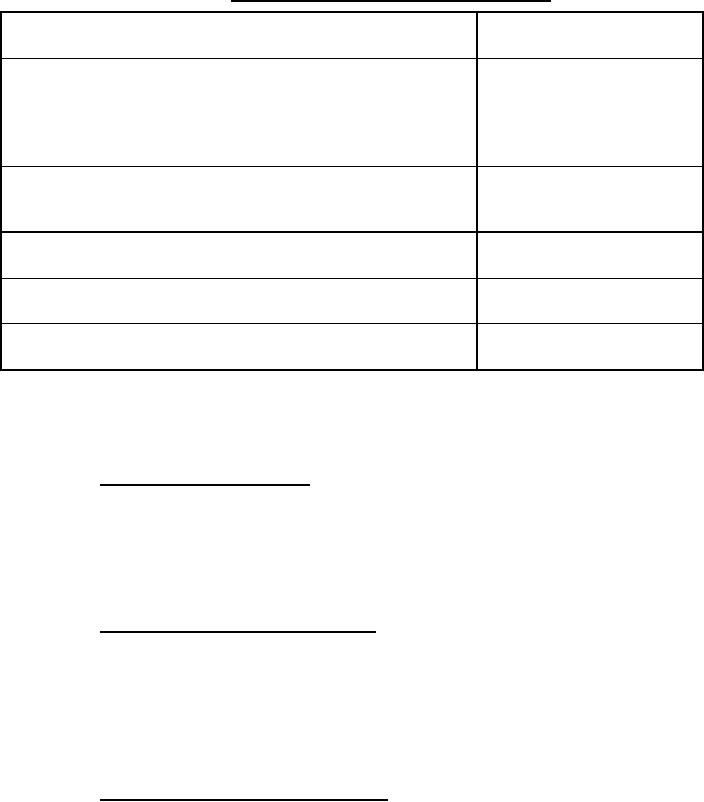

TABLE I. Methods of unit preservation by size or type.

Open/closed bearings 1

Size or type

MIL-DTL-197 method

41B

Up to and including 1.1811 inches

or 30 millimeters (mm) (metric) outside diameter (OD) 2

44B

46B

52B

55B

20B

Over 1.1811 inches or 30 mm (metric)

but not exceeding 16 inches OD 2 3

40B

41B 4

Greater than 16 inches OD or 406 mm (metric)

49B

or greater than 10 pounds (lbs.)

32B

Plain bearings, self-aligning bearings, rod end bearings,

33B

sleeve bearings, and airframe bearings

Optional methods (see 3.3.1)

45B

54B

1

Cleaning and drying shall apply only to open, non-lubricated bearings.

2

Method 40B is required for bearings to MIL-B-17931.

3

Method 20B may be used for bearings with OD over 4.86 inches or over 123 mm.

4

No weight limit when used with supporting container (MIL-DTL-117, type I, heavy duty).

3.3.2 General preservation process. Unless otherwise specified (see 6.2), all bearings

shall be subject to a general preservation procedure. The details of that procedure are

determined by bearing type, closure, and contract or purchase order requirements. The general

procedure consists of the following steps: demagnetization, cleaning, drying, preservation,

lubrication, intimate bagging or wrapping, and unit packaging. These steps are not listed in

sequence and additional steps may be required.

3.3.3 Demagnetization, cleaning and drying. Prior to cleaning, the magnetization of

instrument precision ball bearings shall not exceed a pole strength of two gauss and the

magnetization of all other bearings shall not exceed a pole strength of five gauss. Bearings in

excess of the applicable value shall be demagnetized and retested. Bearings shall be cleaned and

dried according to type and closure and contract or purchase order requirements. Pre-lubricated

bearings shall not be subjected to the cleaning process. Processed bearings shall be free of any

chemical or particulate residue that will have detrimental effect on the life of the bearing.

3.3.4 Lubricants and preservative compounds. Lubrication of bearings and actual

lubricants used shall conform to government prime contract item description requirements. Any

resultant flow-down of item description requirements to a packaging facility shall include the

same item description information (see 3.1.4.1). When lubrication is not applicable, then a

contact preservative compound shall be applied in accordance with contract or purchase order

requirements. When the bearing item description does not specify a contact preservative

compound, then the preservative material shall be as specified in table II. Self-lubricating

bearings, as described within this document, shall not have lubricants or preservative compounds

applied.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business